When that Oberon Design package comes in the mail, you’re not just seeing a beautiful leather journal, notebook cover, or portfolio. You’re seeing the end result of a highly intricate

process involving skilled craftsmanship in embossing, sewing, and more, all done by the hands of real people, right here in the USA. As proud as we are of each piece we make, we’re just as proud (maybe more so!) of the work that goes into making them. Read on for a behind the doors peek at our studio and see that labor of love for yourself!

We begin with a leather hide that is custom-tanned just for us. It is drum-dyed and free of coatings and paints, allowing it to retain a natural look. The dye penetrates completely, making a perfect canvas for our image designs. Drum-dyeing also gives the leather a rich, saturated color and finish that ages to a beautiful patina over time.

Minimizing waste is a crucial part of our mission, so we use a shrewd eye and our “high-tech cookie cutter” when placing pattern pieces so as to get the most out of each hide. We only start creating our leather covers once we receive an order, so from the very beginning of the process, we’re already working with you in mind!

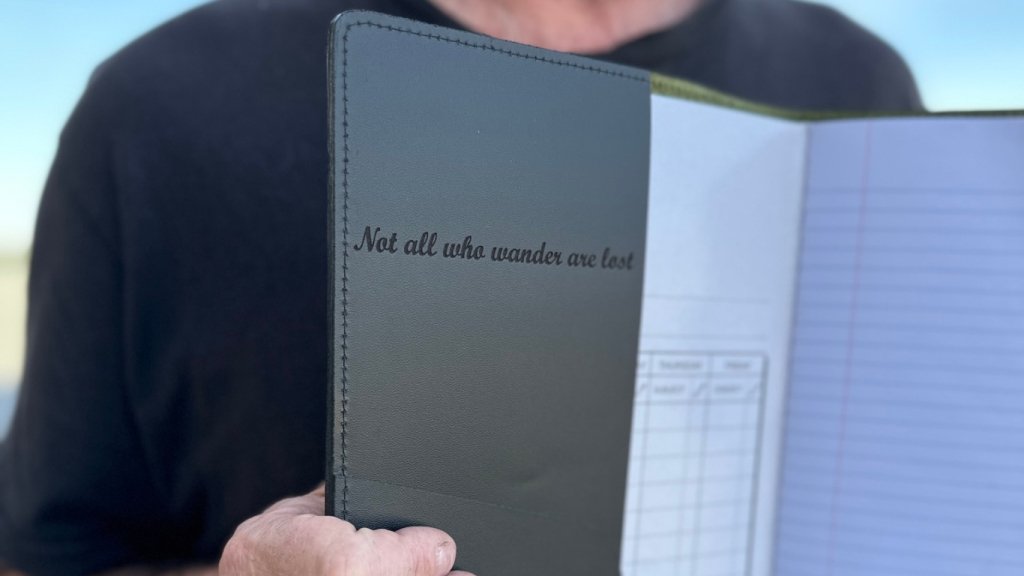

Now for everyone’s favorite part: embossing the design! To do this, we begin with a heavy carved metal plate. Through the magic of high heat, high pressure, and a lot of artisan expertise, the image is essentially branded into the freshly cut leather piece. The metal plates do wear out over time, and occasionally we’ll retire a design in order to extend the life of the plate. These designs will re-appear periodically in the form of our much-anticipated archive specials.

Once the design is complete, it’s on to the practical details. This is where we add components like interior pockets and pen loops to ensure that every Oberon Design item is not only beautiful, but also functional for everyday life.

Next, we make a precise trim around the edges of the leather, readying it for one of our master sewers. Operating the sewing machine to achieve neat stitches is no easy feat, but our artisans make it look effortless. The next step, thread trimming, is just as exacting. Like the rest of our process, it’s done completely by hand with an expertise of experience and precision that leaves the edges looking flawless.

Heading into the final stages, edge dyeing is a crucial step. As some of us will tell you, it can be very tedious, but it is essential! First, the edges are dyed black and left to dry, then dyed and dried again. This process creates a cohesive edge around the outside of the parts that have been sewn together. Then, we buff and polish those edges for a smooth finish.

Lastly, we add the final touch: our leather closure strap and hand-cast Britannia metal button closure. After a three-person inspection process and a quick once-over with our favorite leather lotion, your newest Oberon journal, notebook cover, or portfolio is on its way to you!